Exterior Wood Care Guide

Make every deck, fence, siding panel, and outdoor wood surface last longer—with climate-smart schedules, the right chemistry, and finishes that actually hold up. This pillar consolidates our full cluster so you can jump from high-level strategy to deep how-to in one place.

How to Use This Guide

- Scan the comparison tables to pick the right protocol by wood type and climate.

- Open the linked deep dives when you need step-by-step methods, product selection, or pro troubleshooting.

- Bookmark this page: it’s designed as a permanent reference with year-round tasks and long-term ROI math.

Pro insider note (15+ years maintaining exterior wood across U.S. climates): 80% of expensive failures come from three mistakes—(1) not adjusting maintenance to your local climate, (2) using the wrong finish for the wood species, and (3) applying the first treatment too late or too early. Penetrating systems that match species + climate win the 10-year total cost every time.

Master Map of the Cluster

- Deck Care Encyclopedia → strategy, schedules, chemistry, and fixes:

→ Complete Deck Care Encyclopedia - Finish selection (stain vs sealer, longevity, aesthetics):

→ Deck Sealer vs Stain: Which Lasts Longer? - Climate-specific product picks (salt air, UV, humidity):

→ Best Deck Stain for Coastal Climates (2025) - Cleaning, brightening & chemistry (oxygen bleach vs oxalic acid):

→ Deck Cleaning Solutions: Oxalic Acid vs Sodium Percarbonate

→ How to Clean a Wood Deck Without Pressure Washing - Safety around pools (COF targets, traction upgrades):

→ Non-Slip Deck Coatings: Additives vs Textured Stains vs Strips - Material-specific maintenance (PT lumber, hardwoods, cedar siding, fences, teak):

→ Pressure-Treated Lumber Care

→ Best Wood Fence Stain

→ Cedar Siding Maintenance Schedule

→ Teak Outdoor Furniture: Oil, Seal, or Natural?

Wood Deck Types & Their Maintenance Needs

Pressure-Treated Pine (PT)

- Best for: Value builds, structural framing, high availability.

- Watch for: Chemical moisture at install, green/brown tint, checking.

- Finish: Penetrating oil-based stain after the water-bead test passes.

- Deep dive: PT Lumber Care

Cedar & Redwood

- Best for: Low weight, natural resistance, warm tone.

- Watch for: Tannin bleed, mildew in humid/coastal zones.

- Finish: Semi-transparent penetrating stain; prioritize mildewcides.

Tropical Hardwoods (Ipe, Cumaru, Mahogany)

- Best for: Density, dimensional stability, premium look.

- Watch for: Mill glaze, oil-rich surface resisting penetration.

- Finish: True penetrating oils (not film-forming). Expect more frequent maintenance if you want color retention.

Composite & Synthetic Decking

- Best for: Low-maintenance surface (structure is often PT).

- Watch for: Algae film in shade, slippery surfaces when wet.

- Treat: Non-slip coatings for safety; composite-safe cleaners.

Climate-Specific Deck Maintenance Schedules

Use this table to set expectations by wood × climate.

| Wood Type | Coastal (Salt & UV) | Humid/Wet | Hot/Dry Desert | Cold/Snow | Best Finish Type | Typical Recoat | Notes |

|---|---|---|---|---|---|---|---|

| PT Pine | Rinse salt monthly; stain 3–6 months after build | Biocide-strong cleaner 2×/yr | High-pigment semi-solid | Fall sealing before freeze | Penetrating oil semi-transparent | 24–30 months | Always do water-bead test before first stain |

| Cedar/Redwood | Marine-aware mildewcides | Mildew watch; oxalic brightener | Semi-solid for UV | Avoid salt pellets for de-icing | Penetrating semi-transparent | 18–24 months | Tannin stain → brighten after cleaning |

| Ipe/Hardwoods | Salt wash + true penetrating oils | Ventilation crucial | More frequent light coats | Monitor shrink/swell cycles | Hardwood penetrating oil | 12–18 months | Never film-forming on beachfront hardwoods |

| Composite | Non-slip near pools | Oxygen bleach for biofilm | Minimal UV chalking | Plastic shovels only | — | — | Structure below may be PT → see PT care |

Coastal note: in salt-spray zones, finalize your vertical cladding choice first, so your deck finish schedule aligns with required salt washing and brightening cycles. Then select the product by climate here: Best Deck Stain for Coastal Climates.

Deck Finish Types: What Actually Lasts

- Penetrating oil-based stains: soak in, move with the wood; easier recoat; superior UV block when pigmented.

- Water-based stains: lower odor, faster dry; can struggle on dense hardwoods and fresh PT.

- Film-forming finishes: “paint-like” layer; can peel when moisture cycles under film—high risk on decks.

- Clear sealers: water beads but weak UV defense; color grays fast; yearly treadmill.

Read next: Deck Sealer vs Stain: Which Lasts Longer?

Year-Round Deck Care Calendar (At-a-Glance)

Spring

- Full inspection (fasteners, joists, railings), deep clean with oxygen bleach, brighten cedar/redwood (oxalic), spot repairs.

- Guide: Clean a Wood Deck Without Pressure Washing

Summer

- UV protection check, light maintenance coat if pigment is faded, non-slip audit around water features.

- Safety: Non-Slip Deck Coatings

Fall

- Prime window for full staining before freeze–thaw. Clear debris, confirm dry days, apply penetrating system.

Winter

- Monitor snow loads and water pathways; avoid steel shovels; spot check after thaws.

Cleaning Methods That Don’t Destroy Wood

- Primary cleaner: Sodium percarbonate (oxygen bleach) for organics (mold/mildew) and grime.

- Critical second step: Oxalic acid brightener to neutralize pH, lift rust/tannin, and restore color—especially for cedar/redwood.

- Avoid: High-pressure blasting that raises grain and drives water deep.

Deep chemistry:

→ Oxalic Acid vs Sodium Percarbonate

→ Gentle Cleaning Step-by-Step

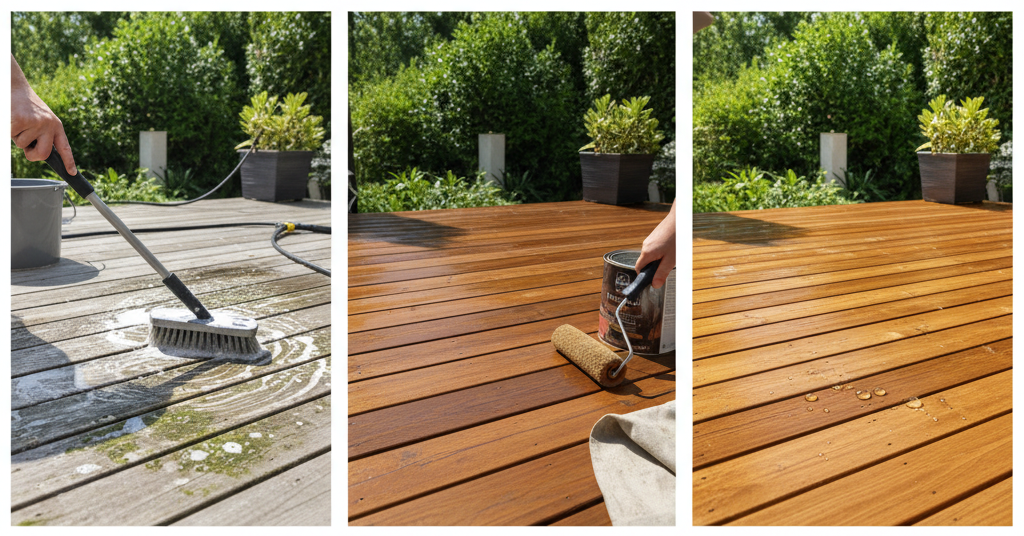

Staining & Sealing Best Practices (Failsafe Protocol)

- Moisture readiness: For new PT, wait 3–6 months; do the water-bead test (must absorb within ~5 min).

- Prep: Clean (oxygen bleach) → Brighten (oxalic) → Rinse thoroughly → Dry 24–48h (longer in humid/coastal).

- Application: Two thin coats, back-brush; maintain wet edge; mix non-slip aluminum oxide additive near pools for 0.60+ wet COF.

- Cure & maintain: Light maintenance wash quarterly in humid/coastal zones; visual pigment check each spring.

PT first-year specifics: Pressure-Treated Lumber Care

Common Deck Problems & Fast Fixes

- Moisture damage/rot: Improve drainage, re-flash ledger, switch to penetrating finish, treat end-grain.

- UV graying: Increase pigment density (semi-solid), shorten recoat intervals in desert/coastal.

- Splintering/cracking: Stop pressure-washing, sand raised fibers, re-oil.

- Mold/mildew/algae: Two-step clean (percarbonate → oxalic), add mildewcide-forward finish in humid zones.

Safety & Slip Resistance (Pool, Stairs, Shaded Zones)

Pool-adjacent decks should target a wet COF ≥ 0.60; the most durable approach is a penetrating stain with aluminum oxide mixed into every coat for nearly invisible traction.

- Best durability: Penetrating stain + aluminum oxide additive mixed into every coat (nearly invisible texture).

- Alternatives: Pre-textured stains (lower longevity), adhesive treads (high grip, higher visual impact).

Full guide with methods & rankings:

→ Non-Slip Coatings

When to Refinish vs Replace (10-Year Cost View)

| Scenario | Upfront | Annualized Care | 10-Year Total | Notes |

|---|---|---|---|---|

| Penetrating stain (deck) | $ | $$ (clean + light recoats) | $$$ | No stripping; predictable cycles |

| Film-forming finish (deck) | $$ | $$$ (peel repairs/stripping) | $$$$ | High failure risk on horizontal surfaces |

| Hardwood + penetrating oil | $$$ | $$ (more frequent, lighter coats) | $$$–$$$$ | Best look; disciplined upkeep |

| Composite surface on PT frame | $$$ | $ (wash) | $$$ | Check PT framing lifespan |

If your exterior scope includes façade work, pressure-test budgets with Crawford Designs’ Wood Siding Cost Calculator to compare true 5/10/20-year ownership before you commit.

Decision help: Sealer vs Stain

Hardware & Fasteners That Quietly Fail Decks

- Upgrade to coated or stainless near salt air.

- Inspect hangers/joist ties annually; replace rust-stained boards.

- Break galvanic pairs (e.g., stainless screws with compatible hangers).

Beyond Decks: Fences, Siding & Teak Furniture

Fences. Penetrating stains avoid peel cycles on vertical grain; easy recoats. See Best Wood Fence Stain for product-type picks and application tactics that extend recoat intervals.

Cedar siding. A seasonal checklist prevents $10k+ surprises; fall coatings are make-or-break (see Cedar Siding Maintenance Schedule). If you’re weighing full-façade investment vs upkeep, Crawford Designs’ Cedar Siding Cost & Maintenance (2025) clarifies lifecycle budgets, and their premium comparison—Cedar vs Shou Sugi Ban vs Thermally Modified Timber (TMT)—shows real patina/aging so you can match aesthetics to maintenance reality.

Engineered / thermally modified options. When movement, humidity, or salt exposure complicate traditional cedar, consider thermally modified or engineered solutions; this overview—Engineered Wood vs Cedar vs TMT—maps climate fit, dimensional stability, and recoat cadence so your deck-area finishes and wall assemblies age on similar schedules.

Teak furniture. 80% of owners should let teak go natural gray (clean only). If you must keep the golden tone, use true penetrating oils and a tight cadence. Full how-to: Teak Outdoor Furniture Care.

Quick-Select: What’s Right for Your Deck?

| If your situation is… | Use this finish | Clean/Brighten cadence | Recoat target | Open this guide |

|---|---|---|---|---|

| New PT deck, temperate climate | Penetrating semi-transparent oil | Clean + Brighten before first coat | 24–30 months | PT Care |

| Beachfront cedar with mildew issues | Penetrating stain with mildewcide | Percarbonate + Oxalic, 2×/yr | 18–24 months | Coastal Stains |

| Ipe deck—keep rich color | True penetrating hardwood oil | Gentle wash quarterly | 12–18 months (light) | Deck Encyclopedia |

| Shady, slippery pool deck | Current finish + Al₂O₃ additive | Non-slip inspection each season | With each coat | Non-Slip Coatings |

Field-Tested Truths

- “Marine-grade” on the label ≠ salt-spray durability. Verify real zinc oxide content and deep penetration.

- Never film-form on beachfront hardwoods; it peels in 12–18 months.

- Clear sealers are a UV treadmill; pigmented systems outlast 2–3× with less labor over 10 years.

- Salt residue blocks penetration—salt wash + oxalic is non-negotiable before staining in coastal zones.

- Non-slip you cannot see? Aluminum oxide in every coat—grip without ugly strips.